Contaminant Detection Using SWIR Camera Technology

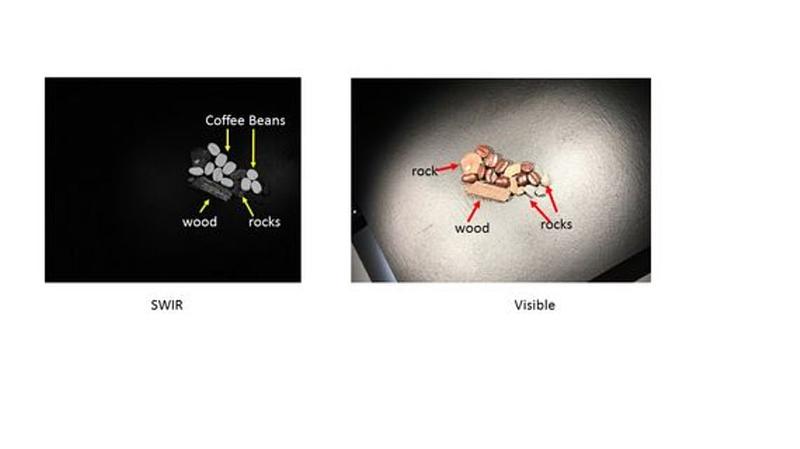

Near- and Short-Wave Infrared wavelength bands (NIR and SWIR) are used in many contaminant-detection or material-grooming applications. Objects may be the same color in the visible, but outside the visible wavelength band, their reflective properties can be very different. This enables SWIR cameras to detect the contaminants and allow systems to remove them from the processing line. In the visible band image to the right, the coffee beans, rocks, and twigs are all brown or are dark in color on a black background. Under 1400-nm light, the coffee beans are very reflective, while the other objects are not, which enables the system to eliminate the contaminants easily. As another example, fresh produce is typically high in moisture, and is dark under 1400-nm light, while the ripe stem has dried out, resulting in a white reflection to the SWIR camera, helping precision agriculture to identify peppers for picking or to detect the stems for trimming before further processing into consumer products. Imaging in bands that select fats or proteins, or in bands that differentiate between types of plastics are other examples where NIR-SWIR imaging delivers strong Return On Investment (ROI).

The compact 2-D MVCam SWIR camera from Princeton Infrared Technologies (PIRT) is a high performance, temperature stabilized, megapixel camera provides users with large Field Of View (FOV) and 12-um pixel resolution. It captures up to 100 full frames per second (fps) with 14-bit linearity and yet no image lag while windows of 512x512 run at 385 fps. The wide and smooth Quantum Efficiency (QE) response makes the PIRT SWIR cameras very versatile, whether the application needs to monitor visible, NIR and SWIR absorbance bands of Chlorophyl, or to differentiate between green and brown coffee beans. When shorter wavelengths cloud images because of scattering, one simply uses a long-pass filter to concentrate on the SWIR images.

1280SciCam

1280SciCam MVCam

MVCam