Moisture Detection Using SWIR Cameras

The Near Infrared (NIR) and Short-Wave Infrared (SWIR) are very useful for monitoring moisture levels and uniformity for food and industrial processes. The water molecule has vibration patterns that absorb energy in many wavelength bands of the NIR and SWIR. By imaging through bandpass filters that are selective for these wavelengths (such as the 1380 to 1480-nm band), or even just illuminating with LEDs in those bands, variations in moisture will be noted. Thus, SWIR cameras ‘see’ uneven moisture across cloth in a textile dye process, or across a roll of paper in a paper mill, or even among cookies or chips coming out of an oven on a conveyor belt. Relative moisture level monitoring is relatively easy to implement with just the cameras and a filter or selective LEDs. Quantifying the moisture level is more difficult, requiring calibration targets and rigorous procedures for reliable results.

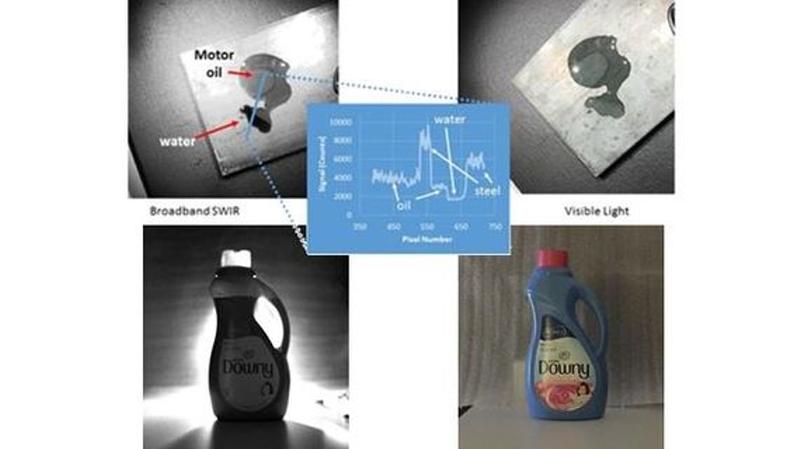

One can even ‘see’ the difference between oil and water while both are on a grey steel background, as illustrated by the images on this page. With visible light imaging, the oil and water reflect the grey background, while the SWIR image shows stark contrast as the water is black to the SWIR camera. Similarly, the fill level of the soap in the detergent bottle is clearly apparent in the SWIR. Here, the light penetrates the bottle plastic and either hits the soap, where absorbs the water band wavelengths or hits the air above the soap, and is reflected to the camera, thereby appearing lighter in the SWIR image.

For machine vision monitoring of moisture levels, checkout the Princeton Infrared Technologies (PIRT) MVCam SWIR camera. It provides HD image width, 12-µm pixel resolution, and 1.3-megapixel images, while running up to 100 full frames per second. The Vis-SWIR wavelength response sensitivity is smooth across the 400 to 1700-nm range (0.4 to 1.7 microns) without wild variations like the colloidal quantum dot (CQD) technology. Those variations hurt detection dynamic range, squeezing the range of moisture levels that can be resolved. The InGaAs detectors also provide much higher Quantum Efficiency (QE), reducing the illumination levels needed, lowering light source costs or the possibility of damaging the product being inspected.

Contact the PIRT Testing Lab to discuss these considerations and to explore the best products for your SWIR application.

MVCam

MVCam 1280SciCam

1280SciCam PIRT1280A1-12

PIRT1280A1-12 Custom Foundry Work

Custom Foundry Work